Today is a big day. Months of design work culminated in the product that we picked up from the University metal manufacturing workshop (The EDMC). Andrea Ambrosetti (machinist, in this picture on the left), Richard Dooler (designer and machinist) and Kevin Smith (boss of EDMC) really did an excellent job of producing the satellite structure. […]

Archive | Progress update RSS feed for this section

Successful Antenna Deployment Test

David Shao, who is one of our volunteers, performed successful antenna deployment tests with the same hardware and mechanism as is destined for use in space. The antenna is held by a nylon wire which is then burned using a resistor (notice the smoke). The antenna is freed under its own tension. Well done […]

GPS receiver arrived

More and more things fall into place. Today, the GPS receiver arrived. This is a big deal because there is quite a process behind acquiring a GPS receiver that works in space. The first challenge was to find a receiver that fits physically into the CubeSat and is suitable for our purposes. In addition, GPS […]

First cut

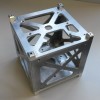

We spent months designing the structure for our CubeSat. This process involved primarily trying to fit all the components inside a very small volume while respecting all the requirements imposed by the CubeSat standard. This was not a trivial task, but it has finally been completed. We produced manufacturing drawings from our 3D computer aided […]

Antenna Deployment Tests

The CubeSat project involves many participants. Sometimes, volunteers even ask us to participate outside of their academic or club work, just because they want to be part of UoS3. Huaiyang and one of his friends are such volunteers who dedicated one week of their summer to do test runs on the antenna deployment mechanism. Thanks […]

First Generation Student Group Finishes

Today was the final presentation of the first group of students to work on UoS3. This group contributed to the satellite in the form of a so called group design project (GDP). A GDP is part of the education that students receive at the University of Southampton where students apply their knowledge to practical problems. […]

Antenna deployment mechanism printed

As part of our objective to test fly 3D printed components on the UoS3 CubeSat the mechanism to deploy the antennas from their stored (launch) to operational position has been printed. Rather than using the common, fused deposition modelling technique, the part was printed using the selective laser sintering method by 3T RPD. The part […]

Successful communication test with SDR

This week the communications team successfully tested the breadboarded communications subsystem using a software defined radio (SDR). An SDR is a simple USB dongle that anyone can plug into a computer and tune to listen to the radio, or alternatively tune to the amateur radio frequencies (145 MHz and 433 MHz) to detect satellites using that […]

First PCB manufactured

The ECS GDP finished fabricating their first PCB today. The PCB combines the payload package, computer and data-handling unit on to a single board to save valuable space inside the 1U CubeSat. Rigorous testing will follow to ensure the board, computer and sensors perform as expected. Update 12 Jan 15 Initial testing of the gyroscopes can be […]

Work begins

September once again brings the beginning of the academic year and with this the next phase in the development of the University of Southampton Small Satellite project or UoS3. This year is focused on the design of the satellite subsystems, verifying those designs and integration into a non-flight demonstration model. Subsequently, we can progress to […]