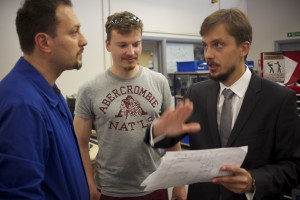

We spent months designing the structure for our CubeSat. This process involved primarily trying to fit all the components inside a very small volume while respecting all the requirements imposed by the CubeSat standard. This was not a trivial task, but it has finally been completed. We produced manufacturing drawings from our 3D computer aided design (CAD) models and discussed how they could be made with the machinists here at our University.

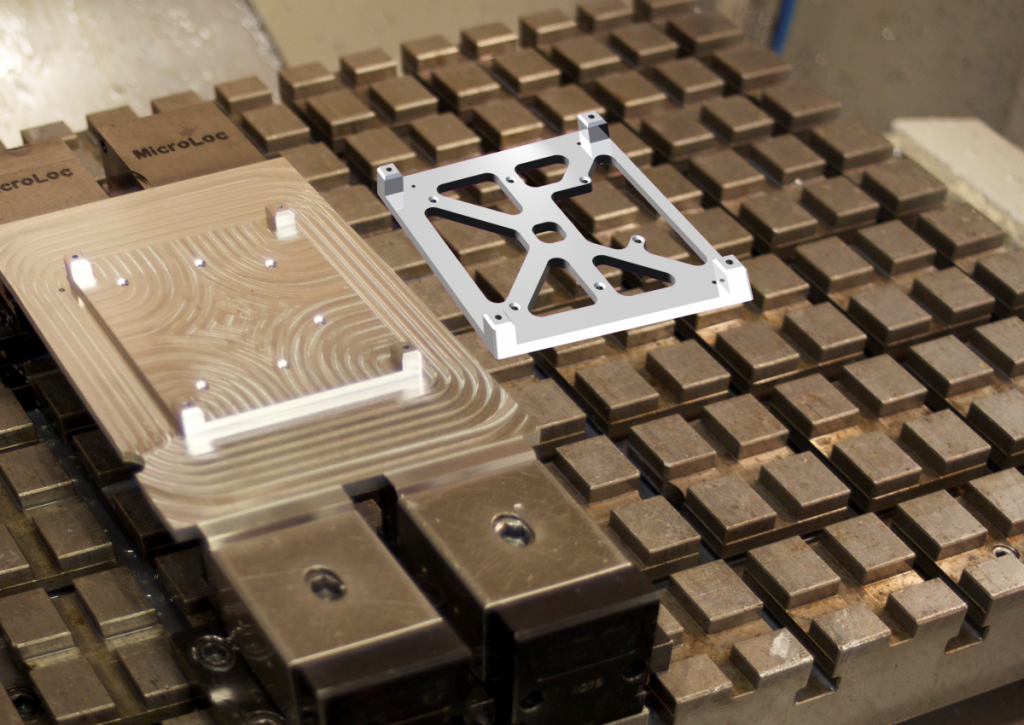

When this process was finished we began cutting the aluminium with one of the CNC machines that the Faculty of Engineering and the Environment at the University owns.

Seeing the machine make first cuts in the plate of aluminium was a truly amazing experience; that was the time when months of planning and designing have come together. One of the most rewarding feelings there are.

Comments are closed.