The attitude control subsystem (ACS) on-board the UoS3 uses a permanent magnet to align one of the satellite’s axes with Earth’s local magnetic field. Such a solution does not any consume any energy, which is a scarce resource on a cubesat. Especially when flying a power-hungry GNSS receiver. However, in order to fulfil our scientific […]

Archive | Project RSS feed for this section

1st Symposium on Space Educational Activities

We presented our work on the UoS3 at the 1st Symposium on Space Educational Activities. It was a workshop that brought together leading European institutions that provide education in the field of Space Engineering. As such, it provided a great opportunity to exchange experiences both regarding cubesat design, manufacture and operations, as well as how […]

Solar panel delivery

Today is a big day for us and UoS3 – we received two of our solar panels today! They were manufactured by DHV Technology, a Spanish company that has been working with us to design and build custom-made solar panels that will fit into our cubesat. So far we only bought two of these because […]

New Semester: 3 New Student Groups

The new semester has started at the University of Southampton and with it, 3 new student teams picked up work on UoS3: The power subsystem is currently in prototype form will be driven to completion by Josh, James, Thomas, Adran and Reece under the supervision of Alex Weddell. The telecommunication subsystem, at this point, is […]

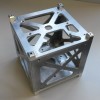

Structure Manufacturing Completed

Today is a big day. Months of design work culminated in the product that we picked up from the University metal manufacturing workshop (The EDMC). Andrea Ambrosetti (machinist, in this picture on the left), Richard Dooler (designer and machinist) and Kevin Smith (boss of EDMC) really did an excellent job of producing the satellite structure. […]

First cut

We spent months designing the structure for our CubeSat. This process involved primarily trying to fit all the components inside a very small volume while respecting all the requirements imposed by the CubeSat standard. This was not a trivial task, but it has finally been completed. We produced manufacturing drawings from our 3D computer aided […]

UoS3 and arts

One of the purposes of UoS3 is to improve the educational experience of the students from across our University. It is common for CubeSat projects to focus mainly, or even solely, on engineering and science students that take part in design, manufacture, and utilisation of the satellites. It is a meaningful thing to do because […]

Computer’s first rehearsal

When many groups of people are making a piece of equipment, like our CubeSat, they have to come up with interfaces that specify how different pieces will fit together. Then you make the pieces according to these interfaces and, if everyone has done everything correctly, the pieces should fit. When we got our first prototypes […]

Watching the mass

The biggest limitation for virtually every satellite is its mass. If the satellite is too heavy the rocket will not be able to take it into orbit. UoS3 will be less than 1.33 kg, so this isn’t a problem. But we still need to comply with CubeSat requirements and keep the mass below the mentioned […]

Approving the manufacturing drawings

Upon finishing the computer aided design (CAD) model of the satellite and verifying, through analysis and review of design, that the structure that will carry all the mechanical loads meets the requirements set for UoS3 we decided to manufacture it. To do this we produced a set of technical drawings and, while some of the […]