Upon finishing the computer aided design (CAD) model of the satellite and verifying, through analysis and review of design, that the structure that will carry all the mechanical loads meets the requirements set for UoS3 we decided to manufacture it.

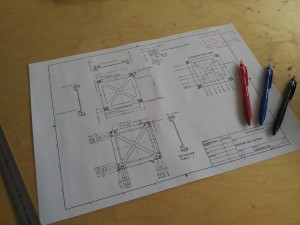

To do this we produced a set of technical drawings and, while some of the analysis was still being carried out, started talking to the actual machinists that will mill the satellite structure out of aluminium. Doing these activities in parallel helped us save time. Making sure that our design is manufacturable, and the drawings correct and complete, saves us future delays and rework, so time and money.

We reviewed several manufacturing companies external to the University as well as our own facilities located on the main campus. Eventually keeping the manufacturing on campus proved slightly cheaper while allowing us to view the whole process. So stay tuned for cool pictures from the workshop!

Comments are closed.