There are many areas on a wingsuit that are less than ideal and the majority of them stem from the human inside the suit. One area of our development is the head and helmet region, we have been looking into how to improve the flow over this area and how to keep the flow attached for longer. Our CFD analyst Chris has been busy….

There are many areas on a wingsuit that are less than ideal and the majority of them stem from the human inside the suit. One area of our development is the head and helmet region, we have been looking into how to improve the flow over this area and how to keep the flow attached for longer. Our CFD analyst Chris has been busy….

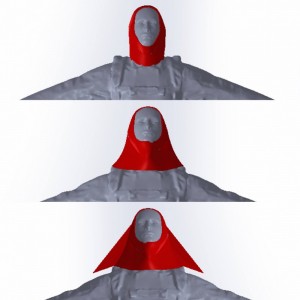

The neck region has a very detrimental effect to the flow over the suit as a whole and we have created some designs to help tackle this issue. These are our 3 main types we are developing; carefully crafted by our computer aided design [CAD] team & currently being analysed in Ansys Fluent, CFD software. We have taken inspiration from a variety of places, most notably downhill skateboarding helmets.

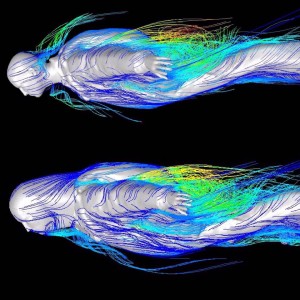

The computer simulations of these cases can take hours/days as the cases need to be run in 3D due to the complex nature of the geometry. Once the cases have been run, it’s up to our team of CFD analysts to crunch the numbers, visualise the flows and make sense of the mass of data that CFD returns.

This image (right) compares the case with no helmet [top] & a case with one of our new helmet designs [bottom] It can be seen quite clearly that the original case exhibits a lot of flow separation on the back of the neck which gives high drag. Our aerodynamic helmet design shows flow that stays attached over the back of the neck which then carries on over the parachute rig on the subjects back, reducing the drag production. This is great step forward for us and the next step is to integrate this onto our baseline model. Watch this space for more info about that coming soon…

No comments yet.