The concept of 3D printing in general is fascinating to me, especially the idea that designs, both creative or functional, can be produced from computer modelling. I have experience with using such printers (both before and during university), and was intrigued when I found out through the lectures that they can be used in combination with stem cells; other examples of its medical applications are producing custom-tailored prosthetics and printing of tissues. As someone who has only printed using plastics, this topic appealed to me.

What is Bioprinting?

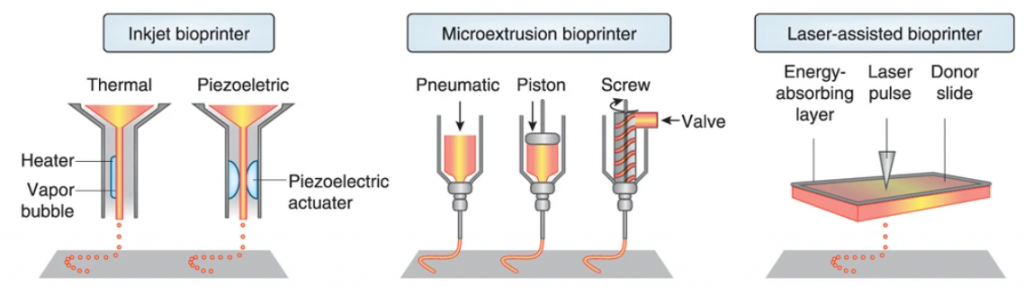

Bioprinting is a process very similar to typical 3D printing using plastic or metal, albeit replacing such materials with desired cell types mixed into a gel (e.g. gelatine) to create what is known as bioink. The mixture is then printed layer-by-layer until the desired structure has been produced. There are three main strategies for bioprinting:

- Inkjet – heat or ultrasound is used to produce pressure to force material from the extruder

- Microextrusion – mechanical means of releasing material

- Laser-assisted – releases cells via the pressure generated by a laser on an absorbing layer

Bioprinting has promise in its applications for printing tissues and organs, such as ears for those suffering from microtia, through printing their cells into a replacement ear. This reduces the need for patients to undergo more invasive surgery.

Other Applications of 3D Printing

Another way in which 3D printing can benefit patients is through indirect means; through creating accurately scaled replicas of organs undergoing surgery, such as hearts, surgeons can plan the surgery ahead of operating. The video below documents how Lucas Ciulean, a child born with an uncommon heart abnormality, was able to recover after surgery in which a replica 3D printed version of his heart was studied ahead of time. When I first watched it, I found it thought-provoking that the technology I had been using for years was capable of providing such valuable insights to patients with atypical conditions. I also believe this video raised an important point regarding minors undergoing surgery; by allowing parents to visualise the surgery planned for their child, these replicas can provide the parents with some comfort and reassurance. In my opinion, this is of the utmost importance since patients, or patients’ guardians, should feel informed and comfortable about any planned procedures.

Another interesting application of 3D printing has been displayed by MIT engineers, in which a prosthetic heart has been produced from soft plastic. The process started similar to the previous example, by taking scans of the patient’s heart and reproducing a 3D model from them; however, it deviates from the prior example since the model is then printed in a softer, flexible plastic. By fitting sleeves around the heart replica, it can mimic the rhythmic pumping of an actual heart through a pneumatic system. This is an interesting contrast to the idea of bioprinting a heart, although I have concerns regarding its viability due to the need for attachment to a pumping mechanism which may impact the patient’s comfort.

My Final Thoughts

The technique of 3D printing has been an interest of mine for years, and expanding this knowledge to the applications discussed above has been a rewarding journey. The current research state of bioprinters is really impressive and by building on the current knowledge, this technology will hopefully become more widely available to aid patients in need. I think that research should continue to innovate in both classical plastic printing, as well as in bioprinting to provide patients with more choices, and a greater level of reassurance and control that the option chosen is best for them.

Very well written, with an excellent format and images. You’ve included interesting statistics and related it to personal ideas which…

This is a very well written blog, the format is as if you are talking directly to me. The ideas…

Love the Batman GIF :)

This is an excellent, well written blog. The narrative is engaging and easy to follow. It could be improved by…

This is a well-communicated blog. The it is written well with good use of multimedia. It could be improved with…