Donor organ transplants

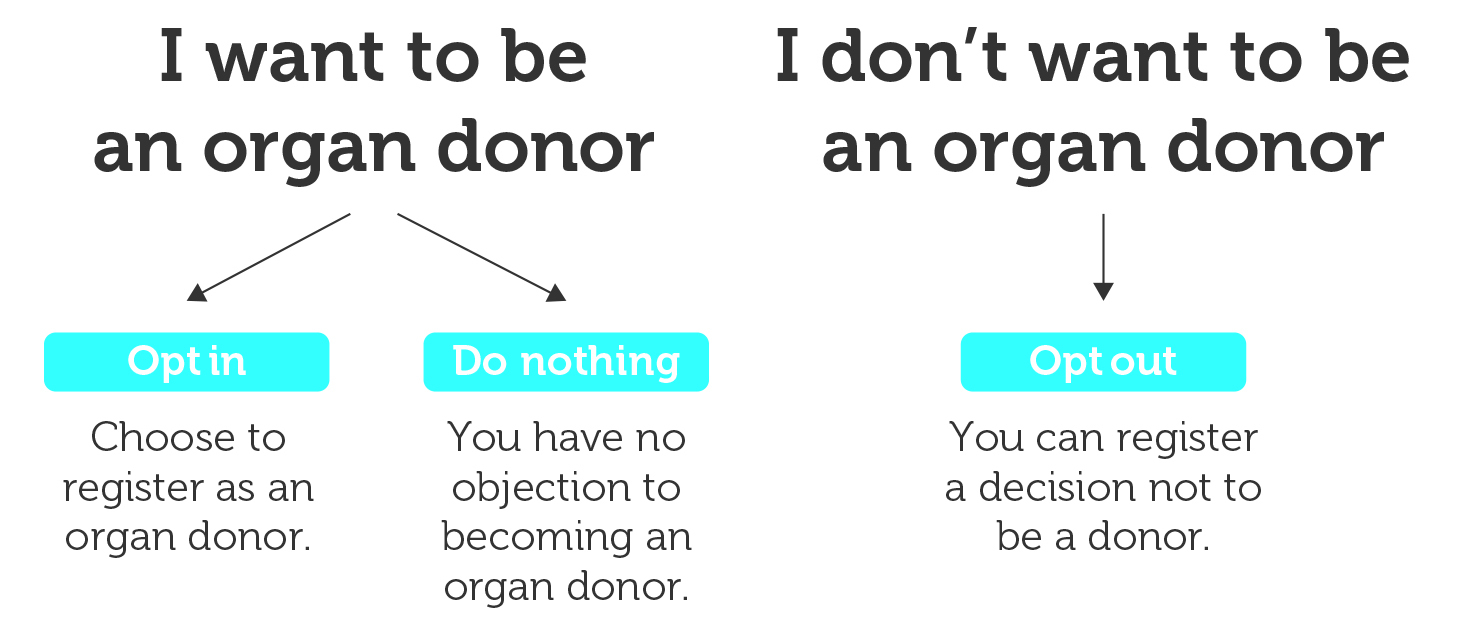

The human body has a limited capacity to heal or regenerate compromised organs. Currently these are normally replaced via transplant from a compatible donor, but there can be complications with rejection when the immune system recognises the transplanted tissue as foreign and there is the initial issue of having enough donors within society to provide the organs needed for transplants everyday. Those of us in the UK should be especially aware of donor shortages, given we must opt out of the organ donor register per the Organ Donation Bill (2019) as consent for donation is automatically assumed otherwise.

A possible solution

Bio-printing uses common 3D printing techniques to construct organs or other bio-materials from base cells in a ‘bio-ink’. Potentially, those waiting for organs could have one purpose printed or their damaged organ repaired (with successful stem cell use demonstrated for both), cutting the risk of rejection and wait time.

Printers?, Ink?, Like a regular printer? Bio-inks are predominantly blends of alginate-gelatine that contain desired cells. The properties of this material must be specialised for its use and the method of printing involved, optimal cell growth and tissue integrity has to be maintained for the cell payload, print temperature and pressure can kill the cells during delivery if not set correctly. Simultaneously the gelatin must be viscous enough for delivery and yet achieve a balance of flexibility and sturdiness once in place to replicate organs as if grown in situ.

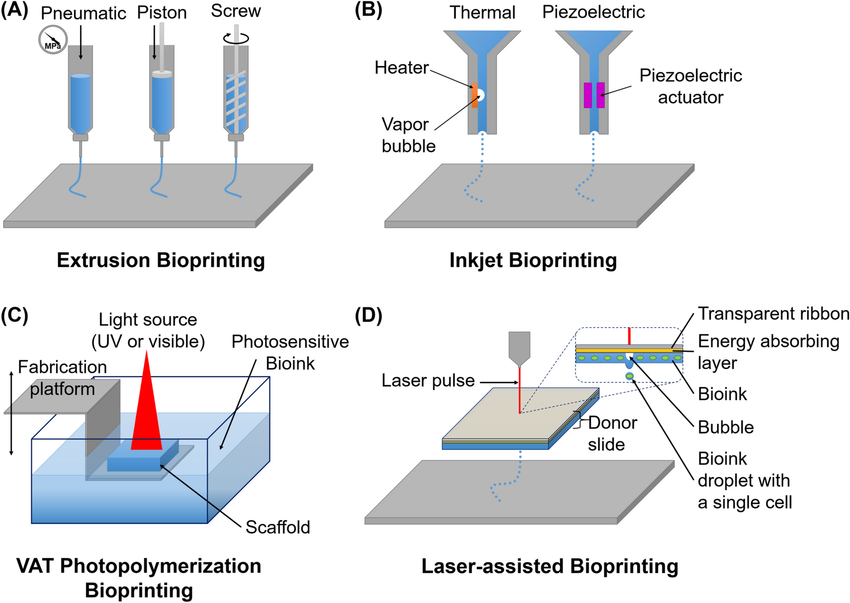

The printers involved vary, but most may be familiar, inkjet printers similar to the one on your desk (and possibly built by the same company e.g. Hewlett-Packard) heat the ink and eject it onto the build plate via an array of nozzles in the printhead. Stereolithography (already used by hobbyists like myself with non-bio photopolymers), targets UV or visible light onto a build plate, upon which the bio-ink undergoes a chain reaction from liquid gelatine to a solid scaffold for growth under light exposure.

Extrusion printers build a structure with supports layer by layer, the material is either pushed out of a syringe in liquid form under pressure via pneumatics, pistons or screws or fed into a controlled heated nozzle (called a hot end), liquified and deposited directly onto the structure, the latter being the same premise as for FDM (Fused Deposition Modelling) printers.

Bio-printing in fiction and societal views

Those of you who’ve read books such as Kiln People or Queen of Angels or watched Westworld know the concerns that can arise with bio-printing. Body modification, cloning and exploitation of humans made through bio-printing have been explored in our media, so what standards can we hold bio-printing to? I myself own two (non-bio)printers, they’re incredibly easy processes to pick up and find equipment for (there have been open source instructions to build your own bio-printer for under £400 from Carnegie Mellon University since 2018) and yet there is no sui generis regulatory body governing the entire process, only partial coverage for the biological material itself under the HTA for tissues and HFEA for stem cells.

My closing thoughts

The concerns above are significant, and yet it seems to me the industry might be getting ahead of being assessed and regulated. Although we’re nowhere near printing the hosts, if someone can inexpensively decide to make their own bio-printers, why don’t specific regulation bodies exist and how could they monitor such possibilities when the process can feasibly be completed in the comfort of your own home.

References

Information on opt-in, opt-out system: https://www.organdonation.nhs.uk/helping-you-to-decide/about-organ-donation/faq/what-is-the-opt-out-system

Ong, C. S., Yesantharao, P., Huang, C. Y., Mattson, G., Boktor, J., Fukunishi, T., Zhang, H., & Hibino, N. (2018). 3D bioprinting using stem cells. Pediatric research, 83(1-2), 223–231. https://doi.org/10.1038/pr.2017.252

Murphy, S., Atala, A. (2014). 3D bioprinting of tissues and organs. Nat Biotechnol 32, 773–785. https://doi.org/10.1038/nbt.2958

Chung J, Kapsa R. (2013) Bio-ink properties and printability for extrusion printing living cells. Biomaterials Science. http://dx.doi.org/10.1039/C3BM00012E

Kirillova A, Bushev S, Abubakirov A, Sukikh G. (2020) Bioethical and Legal Issues in 3D Bioprinting. Int J Bioprint; 6(3):272. doi: 10.18063/ijb.v6i3.272.

S. Vanaei, M.S. Parizi, S. Vanaei, F. Salemizadehparizi, H.R. Vanaei, (2021) An Overview on Materials and Techniques in 3D Bioprinting Toward Biomedical Application, Engineered Regeneration, Volume 2, https://doi.org/10.1016/j.engreg.2020.12.001.

Herzog, Josha & Franke, Lea & Lai, Yingyao & Rossi, Pablo & Sachtleben, Janina & Weuster-Botz, Dirk. (2024). 3D bioprinting of microorganisms: principles and applications. Bioprocess and Biosystems Engineering. 47. 1-19. doi: 10.1007/s00449-023-02965-3.

Open source instructions for a bioprinter from CMU: https://engineering.cmu.edu/news-events/news/2018/03/23-bioprinter-feinberg.html