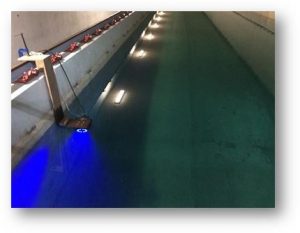

The University MULSER2014 funded Qualisys optical motion capture systems is now in operation in our new towing tank. It is also available for use at other locations including swimming pools as it consists of four underwater and eight above water cameras.

Dr Chris Phillips reports that at the end of March a small group of academics & researchers from both FSI and WUMTIA joined Phil from Qualysis to learn more. We were taken through the capabilities of the Qualysis system, illustrating applications in naval architecture as

well as biomechanics. We were then taken through the crucial above and below water calibration phase to get the targeted ±0.4mm accuracy, before doing some simple trials ourselves.

well as biomechanics. We were then taken through the crucial above and below water calibration phase to get the targeted ±0.4mm accuracy, before doing some simple trials ourselves.

The possibilities this new capability of accurately tracking precise locations, above and or below water, has given us is extensive. With much of the system portable too, we’re not just limited to the towing tank, opening up other test sites and facilities such as in wind tunnels, swimming pool or motion capture platforms. There have been many research and commercial ideas already suggested, including; flexible rudders and hull forms in combination with DIC, sail performance, autopilot evaluations, UAV trials and performance sports analysis.

The first use of the system was for the SESS6067 Wave Energy lab were PhD student James Bowker developed two point absorbers and students tested their response in varying wave frequencies as well as their relative six degree of freedom motion. Once set up the system worked reliably throughout the two days of student testing with 50 students taking part in the laboratory.

Recently James has also used the system to capture the motion response of the wave powered autonomous surface vessel Fleur. The video shows Fleur making her way into the wave and then the motion captured of the markers on her deck.

All posts by Stephen Turnock

Development of Energy Efficient Technologies

We are very pleased that Dr. Abdul Rahim, Managing Director, Europe and Africa, ClassNK, will deliver a seminar talk titled ” Development of Energy Efficient Technologies” on Thursday 9 June between 1200 and 1300 in Room 1125 in Building 176L.

Summary:

A preview of the practical R&D initiative of ClassNK with respect to the development of energy efficient technologies is given in the presentation. The R&D initiative is two fold: to support new regulations and to develop next generation technologies including fuel saving technologies. As for new regulations, some of the NOx reduction technologies including SCR and EGR are briefed. Some of the next generation technology development projects detailed include the hybrid tug boat, use of lithium batteries on board, fuel emulsion in reducing NOx emission, CFRP propeller, liquid hydrogen transportation, and maritime big data centre.

About the presenter:

Dr. M. Abdul Rahim FIMarEST FRINA,

Managing Director, Europe and Africa, ClassNK

Abdul Rahim started his career with Cochin Shipyard building Panamax bulk carriers and the first generation of double hull tankers. Later, after receiving masters and doctoral degrees in Ship Structure from Hiroshima University, Japan, he joined ClassNK in Tokyo, and worked for ClassNK ever since. After long stints in Japan and Singapore, he is currently the Managing Director, Europe and Africa of ClassNK, based in London.

He received the Singapore Joint RINA and IMarEST Branch Award in 2004 and the Stanley Gray Medal of the IMarEST in 2005 for his works on the development of Advanced Structural Rules which was the forerunner of IACS Common Structural Rules. He published more than 60 technical research papers mainly on ship structures.

Science of Ships on tour in Dorset

A team of ship science students from Team Hydra and FSI PhD students helped out at the very popular Purbeck School science fair on a recent Saturday afternoon. They provided a series of hands-on activities investigating the science of ships including the ‘golf ball challenge’ asking how many Golf balls can be placed in a floating container? They also ran a Wind Tunnel demonstration of the fluid dynamics of drag. In all 50 low drag Lego vehicles were tested to assess their energy efficiency at transporting a cargo of marbles. Great fun was had by all, with a total of 600 visitors.

A team of ship science students from Team Hydra and FSI PhD students helped out at the very popular Purbeck School science fair on a recent Saturday afternoon. They provided a series of hands-on activities investigating the science of ships including the ‘golf ball challenge’ asking how many Golf balls can be placed in a floating container? They also ran a Wind Tunnel demonstration of the fluid dynamics of drag. In all 50 low drag Lego vehicles were tested to assess their energy efficiency at transporting a cargo of marbles. Great fun was had by all, with a total of 600 visitors.

We now have a number of activities that we can supply or provide assistance with that helps promote Engineering and in particular of course maritime engineering opportunities to those who are not necessarily aware of the many exciting career opportunities. Please get in touch if you wish to discuss how we can help.

Challenges and Developments in Maritime Safety and Security Assessment

Professor Jin Wang, Director of Liverpool Logistics, Offshore and Marine (LOOM) Research Institute at Liverpool John Moores University will deliver the next FSI invited seminar on “Challenges and Developments in Maritime Safety and Security Assessment” this thursday 26/05/2016 in Boldrewood Innovation Campus B176 Seminar Room 2013, 12:00-13:00

You are warmly welcomed to join us.

Abstract

Safety and security assessment has been increasingly used to support maritime system design and operation. There has also been a growing international recognition that security issues of maritime systems need to be reviewed. This presentation will address major challenges and developments in maritime safety and security assessment. In particular, areas covered include regulatory regimes in maritime safety and security, IMO’s formal safety assessment, sea port security modelling, and piracy related ship operations together with case studies. Some advanced techniques for maritime safety and security assessment are outlined to demonstrate their potential application.

Biography

Jin Wang is Professor of Marine Technology and Director of Liverpool Logistics, Offshore and Marine (LOOM) Research Institute at Liverpool John Moores University (LJMU), UK. Following just less than 5 years’ research as a research associate at Newcastle University, he joined LJMU as a lecturer in 1995, and was promoted as Reader in Marine Engineering and Professor of Marine Technology in 1999 and 2002 respectively. He has been involved in maritime safety and security for the past 25 years. His extensive publications include 2 research monographs and more than 100 SCI cited journal papers relating to maritime safety and security. He has completed supervision of more than 40 doctoral/postdoctoral researchers in the fields of maritime safety and security.

Hydro team is gearing up for this summer's contest

Preparations are well underway in Southampton by the student team looking to compete in HYDROcontest 2016. This competition brings together engineers and naval architects from all over Europe and beyond to face technical and management challenges.

The University of Southampton team took part for the first time last summer. One of the company partners ABB was looking for a student to take up an industrial challenge of optimising the hydrodynamics of an electrical pod (thrust unit) for a six month internship at Hydros Innovation in Lausanne.

One of our MS students, Nicolas Verkant member of the 2015 Southampton Hydro Team applied as he was looking for a complex and interesting project to begin my career with. It was great news that he was selected and took up the challenge starting in mid February. Nicolas reports, ‘ I spent a few days discovering the goals, constraints, software and geometries. I ran a few simulations in order to find the correct setups before starting the optimisation process. The project really is interesting as a R&D study and also because it is a concrete case that may improve maritime transportation efficiency. The great quality work of the 2015 Southampton Hydro Team has been determinant for my application for this project. Therefore I really encourage people to take part in such a great adventure as this will develop knowledge and skills in very diverse fields, and it may even bring career opportunities. Good luck!’

Ariadna Pons Forn, MSc Yacht & Small Craft 15/16 and Marion James, PhD research student in the Fluid Structure Interactions group, went to the RINA headquarters in London on the 24th of February 2016 to attend the Maritime Project Management conference. They thank ABS and BMT for supporting them with sponsored student places.

Several speakers discussed the challenges related to the management of concept design projects. In addition, the increased complexity of working in a multi-cultural ship building project was raised. Ariadna and Marion learnt key points to ensure good communication in the multi-cultural and multi-discipline project that is the Southampton Hydro Team.

www.SouthamptonHydroTeam.co.uk

Science of Ships

Ship science are participating in this year’s University Science and Engineering week activities on Saturday 12th March on our Boldrewood Innovation Campus. All are welcome – see University website for more information.

This is a great opportunity to meet staff and students and learn about some of the technical challenges involved in designing ships and offshore structures. A series of hands-on activities and demonstrations of the wave crawler ‘Fleur’ in the towing tank will be available for all ages to explore.

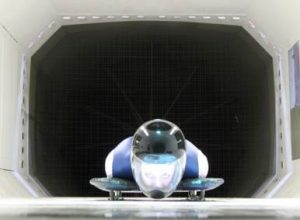

Prof Turnock will be giving a talk ‘Headfirst to success’ in the LR Auditorium at 11:25 and 14:45. In this he will explore some of the science and engineering behind performance in the wintersport of skeleton and also the links into Ship Design.

Whipping and Springing of Ships

Prof Nigel White will be giving the FSI seminar on Thursday 10th march, 12;00-13:00 in B176L room 1125. All are welcome.

Typically, Lloyd’s Rules for the design and construction of ships develop on a largely evolutionary process, however there are often very rapid advances in ship size or design which mean that the evolution process is questionable. The rules and design procedures are also updated on the basis of improved design technology. There has been a huge growth in the size of container ships, in 2000 the biggest ships were 8000 TEU with a length of 300m and beam of 43m, today the ultra large container ships (ULCS) 21,000 TEU have a length of 400m and beam of 60m. This growth is testing the existing evolutionary process, however current computer power means that we can develop procedures that allow us to assess the very complex effects of whipping and springing on the structure of these ULCS.

Containerships are unique in that they have very large deck openings, long hull forms, large bow flare and operate at fairly high operational speeds (roughly 18 knots or over). Each of these pose challenges on their own, but when combined the effect is potentially even more severe. The large deck openings mean that the torsional rigidity of the vessel is low and very high strength and thick steel is required for the deck and hatch coamings, the bow flare and high speed mean that the impact loads due to waves are high (whipping), the long length means that the natural vibration frequency of the hull girder is low and close to the encounter wave period due to the high speed (springing). LR has been working on the assessment of these issues over recent years and has taken the work developed by the universities back in the early 90s (including Southampton) into practical procedures that can be consistently applied.

The presentation gives an oversight into some of the issues related to the assessment of whipping and springing for ULCS. The need for such procedures was highlighted by the recent container ship total losses where whipping was a contributory factor.

Biography

Nigel is a Senior Principal Hydrodynamicist at Lloyds Register and works in the Structural Analysis and Hydrodynamics research group. He has also been recently elected as a Visiting Professor at the University of Southampton in the Ship Science department. Nigel has been with LR for 23 years and is the lead engineer for the development of Lloyds Register’s procedures in areas related to hydrodynamic expertise including ship motions, hydroelasticity (whipping/springing responses), impact loads, sloshing loads, dynamic load application, fluid structure interactions, etc. for all ship types. He has also been involved in many of the IACS working groups involving loads on ships.

Optimal trim control of high speed craft

Our FSI seminar series continues with Dr Melek Ertogan from Istanbul Technical University on Thursday 3rd March from 12:00-13:00

Optimal trim control of high speed crafts in calm sea is being studied in the most recent project. The purpose of the automatic trim control is to improve fuel efficiency, safety and comfort of passengers in a vessel. Trim tabs, interceptors, and sterndrive engines can be used to control the trim of a high speed craft.

The trim tabs and the interceptors were mounted on a craft Volcano71, in length 10.86m, for the real-time applications. The sterndrive engines of a Volcano71 have 2×380 HP and it reaches maximum of 40 knots. The pulse width modulation (PWM) drivers were provided for the interceptor, the trim tabs and the sterndrive systems of the gasoline engines can be manually trimmed. By the end of this project, they will be automatically trimmed by employing the mechatronic setup and an algorithm.

The energy saving systems were operated manually in calm sea for system identification purposes and observing maximum effects. After finalizing the simulation studies of the optimal trim control on the system identification model, the investigations of full scale trials will be realized. Performance of the automatic trim control for a high speed craft can be evaluated with a GPS-aided inertial measurement unit (IMU) at the same motor power while a trim tab, an interceptor, and/or sterndrive system are active and off. It is aimed that the optimal trim control provides up to 30% energy saving.

Biography

Dr Melek Ertogan received B.Sc. degree from the Naval Architecture and Marine Engineering Department, M.Sc. degree from the Naval Architecture Department, and Ph.D. degree from the Mechanical Engineering Department from Istanbul Technical University, Istanbul, Turkey, in 1998, 2003, and 2012, respectively.

Previously, she was a Naval Architecture and Marine Engineer in the industry. She was then a Research Assistant, in the Naval Architecture and Marine Engineering Department, Istanbul Technical University, Istanbul, Turkey, from 2000 to 2004. Since 2006, she has been a Lecturer at the Marine Engineering Department, Istanbul Technical University. Her main research interests include ship automation and control, marine mechatronics, and intelligent systems.

Looking for Maritime Smallpeice participants

Since 2001 until recently FSI/ship Science hosted week long Marine Technology Experience courses each July. These were typically for 90-100 Year 9 students, lasted 4 days, involved a combination of hands-on activities, visits and inspirational talks.

This year the Smallpeice Trust will be celebrating its 50th anniversary and to celebrate this landmark, they are trying to find 50 former students to feature in a 50th anniversary book. If this applies to you or someone you know please get in touch – see details in pdf below

SMALLPEICE TRUST 50 YEARS 50 STORIES

Hybrid Technology for Marine Applications and The Hour Of Power

Our seminar today at 12:00-13:00 in B176/2013 is to be given by John Haynes from RIB & High Speed Craft, Shock Mitigation

Abstract:

Hybrid technology is being utilised by many transport sectors and industries around the world. The marine industry is now recognising the potential of utilising hybrid power and innovative propulsion systems for vessels in the sub IMO / sub 24 metre professional sector.

The Hour Of Power concept enables vessels to run in and out of port for an hour on electric with battery power – then carry out their open sea work on diesel power. The aim of this innovative hybrid solution is to enhance conventional power and propulsion systems. Vessels can reduce emissions and improve fuel consumption whilst extending engine maintenance periods and engine life. The Hour Of Power focuses on viable hybrid solutions linked to vessel work cycles and engine duty cycles. For commercial and professional organisations the concept of running vessels with zero emissions at up to 10 knots for one hour will shape decisions that lead to improvements of in-service systems and procurement of next generation vessels. The overall objective is fuel saving, reduced emissions, additional redundancy and improved efficiency by all means.

Certain maritime sectors are potentially well suited to hybrid diesel / electric systems. These include ferries, harbour tugs, pilot boats that have relatively consistent duty cycles. The Hour Of Power concept lends itself to Wind Farm Service Vessels (WFSV) operating in the ongoing wind farm maintenance phase. For military applications hybrid systems, including battery / electric with diesel, are relevant to patrol, interception, loitering and autonomous vessel duty cycles. As Hybrid technology is generally scalable, proving in the sub 24 metre sector will enable scaling to larger vessels. An example is WFSV applications scaling to offshore supply and patrol vessels.

Biography

HYBRID: Organiser of conferences including: Hybrid Marine Power & Propulsion (2015) / Next Generation Marine Power & Propulsion (2016). December 2015 presented to high level DNV-GL oil & gas industry group in New Orleans on ‘Hybrid Opportunities for Workboats’. January 2016 presented to Superyacht Forum on ‘Hybrid Opportunities for Superyachts’.

Associate Fellow of The Nautical Institute, Commercial Yachtmaster Ocean, Advanced Powerboat Instructor. Subject matter expertise includes 30 years professional sector training / consultancy / product development – focussed on the sub IMO / sub 24m sector. Chairman of conferences for RINA and IQPC. Specialist articles on future requirements / new technology for international publications including: Ship & Boat International (RINA), Maritime Pilot Journal, Seaways, Maritime Reporter, Marine Link, Marine News, Maritime Journal, Powerboat & RIB, Yachting Matters (Superyacht), Defence Management Journal, Defence IQ. Founder of the RIB and High Speed Craft Directory www.ribandhsc.com